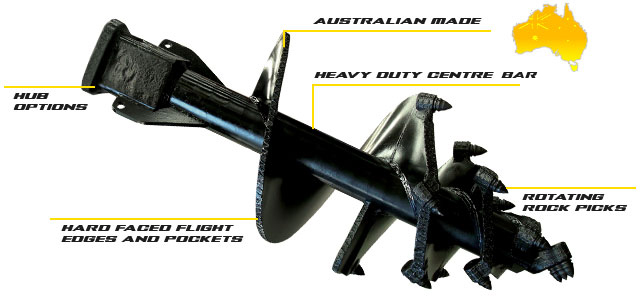

Extreme rock drilling

Tapered rock augers are designed to drill in extreme rock conditions. The engineered design cutting system maximises penetrating abilities of the rotating pick tooth. The design enables the teeth to fracture the rock, allowing for penetration into ground normally unachievable with a standard auger.

Learn more about augers

Gain insight on correct drilling procedures, improving drilling performance, maintaining your equipment, cutting head design, and which teeth to use for varying ground conditions.

Australian made quality

Over 30 years of auger design and manufacturing using the highest quality materials has resulted in an efficient cutting head design and optimum flight pitches to provide maximum soil removal in all ground conditions.

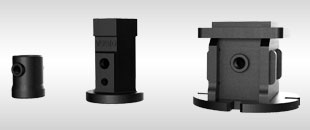

Hub Options

Square, round and hex hub options available to suit your existing drive unit or drilling rig.

Size options

Your tapered rock auger can be made to any length and to your preferred drilling diameter.

Hard-faced edges

A hard-faced finish is applied to the flight edges and pockets of the tapered rock auger to insure a longer life.

Heavy duty centre bar

Heavy duty high grade steel hollow bar ideal for handling the most difficult rock conditions.

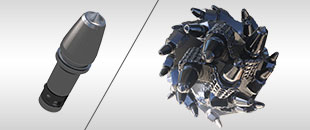

Rotating rock picks & pilot

Heavy duty tungsten carbide conical teeth (rotating rock picks) engineered to maximise your drilling performance through fracturable ground through to very hard rock.

Features & benefits

- Heavy duty build

- Heavy duty centre bar

- Rotating pick teeth and pilot

- Hard faced flight and pocket edges

- Australian Made Quality using superior materials

ALL RIGHTS RESERVED -

ALL RIGHTS RESERVED -