2 Speed drives for 20-28 tonne excavators

Digga has long been at the forefront of innovation in drilling technology, consistently delivering advanced solutions that improve performance, efficiency, and operator control. That legacy continues with the Digga Two Speed Drive — the only two-speed anchor drive on the market purpose-built for pendulum drilling applications. The PDT25 to PDT50 Range comes standard with Digga’s revolutionary Halo alignment system, providing real-time visual feedback for perfectly vertical drilling—eliminating the need for a spotter and freeing up labour for other tasks on-site. 2 Speed drives offer speed when you need it or higher torque when the going gets tough. It's like owning 2 drives in 1.

- High speed, low torque mode – Perfect for small-diameter screw anchoring, rapid spoil removal, and cleaning the base of the hole. Tasks that typically require speed, such as finishing or clearing out loose material, are completed faster and more efficiently.

- Low speed, high torque mode – Ideal for heavy-duty drilling applications using large-diameter screw anchoring, especially in tough, compacted, or rocky ground. This setting delivers the brute power needed to break through challenging conditions without stalling or overloading the drive.

The 'PD' (Premium Drive) range of drilling drives has been the workhorse of the industry - With innovative ground-breaking design features that keep it ahead of the game; such as the development of the Digga/Danfoss Bell motor, which was specifically designed for Digga attachments, utilising DANFOSS Geroler technology, significantly reducing the weight, and overall length of the anchor drives.

Learn about anchor drives

Pair your drive to suit your machine type and achieve optimum performance, find out how to avoid costly repairs, and how the anchor drive has technologically developed over the years.

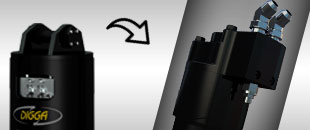

Built-In ECV

Digga’s Energy Control Valve also known as Swoosh Valve can be fitted to all PD drive units for screw anchoring applications. ECV comes standard on all Digga anchor drives.

Compact & powerful

Digga’s range of drilling drives was developed for the professional driller - utilising Geroler technology by Danfoss, the drives design significantly reduces weight whilst delivering outstanding performance.

Industry leading performance

By utilising the Danfoss Bell motor, the anchor drive will accept 60kW of power, delivering exceptional power-to-speed ratio when coupled with the industry leading Digga planetary gearbox.

2 Speed Controller

Operate between 2 speeds from high and low speed settings. Reach a high speed for clearing and removal, and a low speed for dedicated large applications. The 2 speed switch can also operate with a mounted remote joystick, or a floor mount.

Advanced design

The Digga gearbox utilises a two-piece shaft design, the shaft is a separate component to the planetary carrier, isolating the planetary gears from the pushing, pulling, and bending forces generated by the host machine.

Precision accuracy

Now included in all PDT25 - PDT50 Anchor Drives, the new innovative Halo alignment system ensures holes are drilled plumb and reduces the need for in-hole angle adjustments. The highly visible LED indicator wraps around the Anchor drive and will shine green when straight, allowing you to never take your eyes off the job to realign your auger.

Australian made quality

Digga drive units are made right here in Australia from quality materials. Digga is a proud Australian manufacturer committed to keeping jobs in the country.

| Specification | PDT25-SV | PDT30-SV | PDT40-SV | PDT50-SV |

|---|---|---|---|---|

| Rec Flow Range | 40-180lpm | 40-180lpm | 40-180lpm | 40-180lpm |

| Max Torque | 27,373Nm | 31,829Nm | 33,733Nm | 39,224Nm |

| Motor | 6k Geroler | |||

| Pressure Valve Fitted | Included | |||

| Energy Control Valve | Optional | |||

| Case Drain Required | Required | |||

| Max Pressure | DO NOT EXCEED 240Bar @ 150lpm | |||

| Max Flow | DO NOT EXCEED 180lpm @ 200bar | |||

| Max Power | DO NOT EXCEED 60Kw (80 hp) | |||

| Overall Length | 1217mm | 1217mm | 1217mm | 1217mm |

| Diameter | 355mm | 355mm | 355mm | 355mm |

| Weight (no frame/hitch) | 309kg | 309kg | 309kg | 309kg |

| Std Output Shaft | 100mm Square | 100mm Square | 100mm Square | 100mm Square |

| Swing Control | Optional | |||

| Diggalign | Optional | |||

| Halo | Included | |||

ALL RIGHTS RESERVED -

ALL RIGHTS RESERVED -