Anchor Drives for Stand & Ride-On Mini Loaders

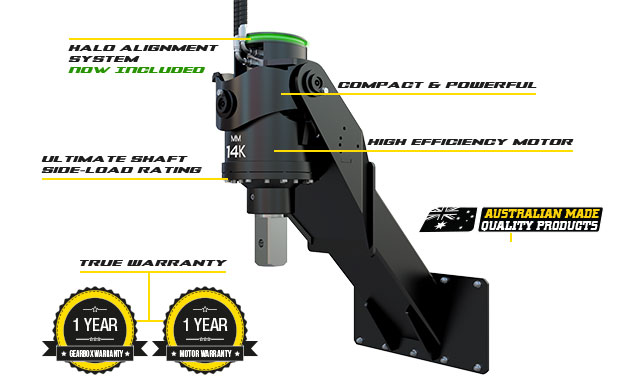

The MM14K Series screw anchor drives are engineered specifically for domestic and light commercial screw piling applications. These compact yet powerful units are designed for stand-on mini loaders, making them ideal for operations in confined spaces with low head clearance.

Offering dependable performance you'd expect from Digga, the MM14K drive is perfect for foundation boring, and ground screw installations. Its standout feature is the innovative gimbal mounting, which enhances reach and flexibility—particularly suited for mini loaders. the MM14K now comes standard with Digga's patented HALO alignment system which allows you to install screw anchors at any angle with 99.5% accuracy without the need for expensive incab alignment systems.

Though small in size, the MM14K drives produces a nominal torque rating of approximately 14,000 Nm. It handles up to 25 kW of continuous hydraulic power and operates at a peak pressure of 205 bar.

Manufactured proudly in Australia from quality material, the MM14K Drive is also available in several other mounting options:

: Excavator Mount & Skid Steer Loader Frame

What are anchor drives?

Find out what screw piles are used for, and what machines you need to install them. Learn the process of choosing the perfect screw anchor drive, and what info Digga uses to determine which drive is perfect for your job!

Compact & powerful

The lightweight, compact, and high-torque gearbox design matches the torque output of larger units like the Digga PD15, while improving maneuverability in tight areas when mounted on a boom.

Why use a gimbal mount?

The gimbal mount reduces overall drilling setup length by eliminating traditional machine linkage, enabling work in areas with height restrictions while allowing for longer augers and screw anchors to be used.

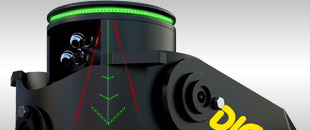

HALO (Now Included)

The HALO alignment system integrated in the auger hood provides real-time feedback. When fully green, it confirms the drive is vertically aligned. If misaligned, the lights give directional guidance to return the drive to plumb. Learn More about HALO

An Industry leader

Backed by over 40 years of engineering expertise, these drives feature a high-efficiency Char-Lynn Bell hydraulic motor that can accept up to 25 kW at a maximum pressure of 205 bar (at 70 lpm) for exceptional power output.

Advanced design

The gearbox includes a two-piece shaft design, which separates the shaft from the planetary carrier to protect the planetary gears from forces transmitted by the host machine such as pushing, pulling, or bending.

Unmatched side load ratings

With more than twice the side load capacity compared to competitors, this design maintains bearing loads effectively under torque, enhancing durability and performance.

Australian made quality

Proudly made with quality materials in Australia, Digga maintains a commitment to local manufacturing and employment.

| Specification | MM-14K - Mini Loaders |

|---|---|

| Max Torque @ 205 Bar | 14,206 Nm |

| Motor | Geroler |

| Pressure Valve Fitted | N / A |

| Energy Control Valve | N / A |

| Max Pressure | Do not exceed 205 bar @ 70 lpm |

| Max Flow | Do not exceed 70 lpm @ 205 bar |

| Max Continuous Power | Do not exceed 25Kw (33hp) |

| Gearbox Length | 640 mm |

| Gearbox Diameter | 290 mm |

| Gearbox Weight | 66kg |

| Std Output Shaft | 75 mm Square |

| Hitch Weight | 129kg |

| Hitch Length | 1750mm |

| Hitch Width | 630mm |

| HALO | Included |

ALL RIGHTS RESERVED -

ALL RIGHTS RESERVED -