Full range of torque measuring solutions

Digga offers a range of torque measuring solutions which are accurate, operator friendly and easy to install. Our products ensure that the correct torque specifications have been met and accurate data has been recorded for every job carried out.

To Suit 13,000 - 95,500Nm Anchor Drives

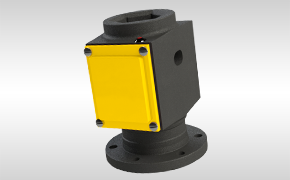

Torque Hub

The Torque Hub measures actual live torque generated by the drive unit by way of a load cell. This converts the mechanical force into digital values that the operator can read and record. The display is connected via the TorqApp and through WiFi, for a more reliable connection.

The Torque Hub accurately shows the inclination of the pile and allows the operator to manually add pile depth. The data is stored internally and can be exported by the operator to produce pile reports for engineers.

To suit anchor drives (13,000 to 95,500Nm) with 75mm or 100mm Square shafts sizes.

To Suit 110,000 - 500,000NM Anchor Drives

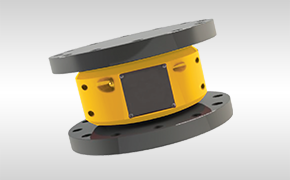

Torque Spool

Utilising the same technology as the Torque Hub, the Torque Spool has the load cell located between two flanges. This allows the operator to change the unit between different size output shafts and different drive tools avoiding adaptors and the need for multiple units.

The Spool uses the same display as the Torque Hub which is also connected via WiFi for a more reliable connection. The Torque Spool is over 99% accurate, it also shows the inclination of the pile and allows the operator to manually add pile depth. The data is stored internally and can be exported by the operator to produce pile reports for engineers.

To suit anchor drives (110,000 to 500,000 Nm).

To Suit 6,000 - 500,000Nm Anchor Drives

Pressure Differential Gauge

Differential Pressure Gauge uses transduces located within the drive unit to calculate actual pressure received to the power head. The calculation is achieved by measuring the pressure from the feed line and subtracting the back pressure in the return line.

The differential pressure is then displayed in the operator’s cab. The operator can cross reference the displayed figure with the supplied torque chart to determine the theoretical output torque of the

drive unit.

To suit anchor drives (6,000 to 500,000 Nm).

ALL RIGHTS RESERVED -

ALL RIGHTS RESERVED -